Automotive

Industry Solutions

Manufacturers in the automotive industry are faced with new challenges every day, such as the EU requirement to significantly reduce greenhouse gas emissions.

From 2020 onwards, a limit value of 95 grams of CO2/km will apply to all newly registered passenger cars. In 2015, the limit was 130 grams. The new limit value corresponds to consumption of 4.1 liters of gasoline or 3.6 liters of diesel per 100 kilometers. The major challenge now is to dramatically reduce energy consumption. Engines will also have to maintain the defined performance standard, and preferably even exceed it. Reproducible quality in series production with the fastest possible manufacturing times is the key requirement in this industry.

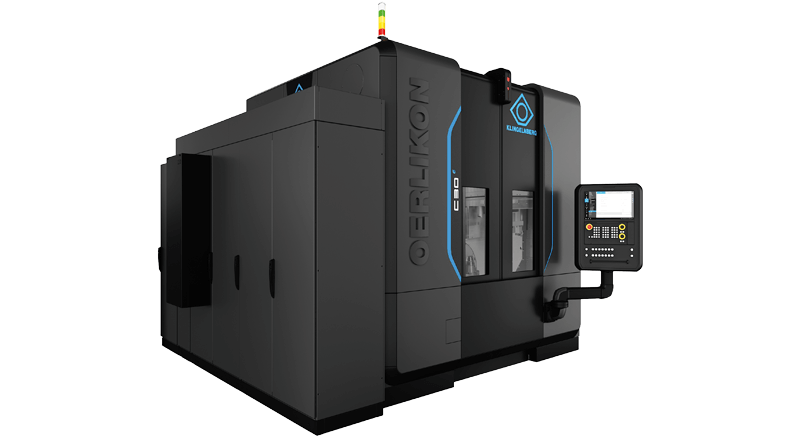

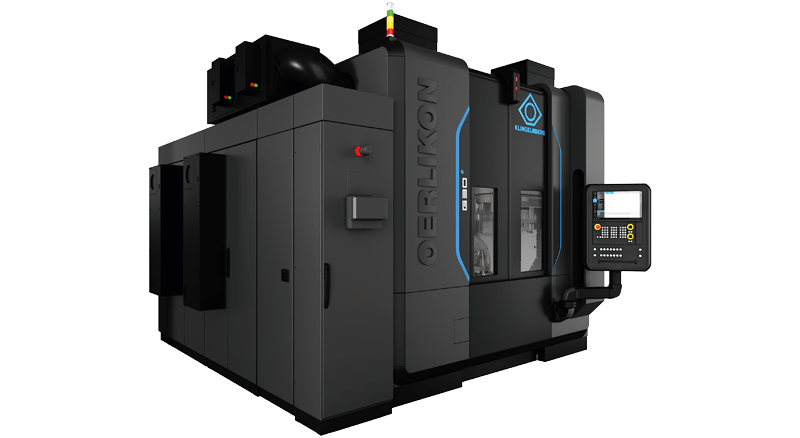

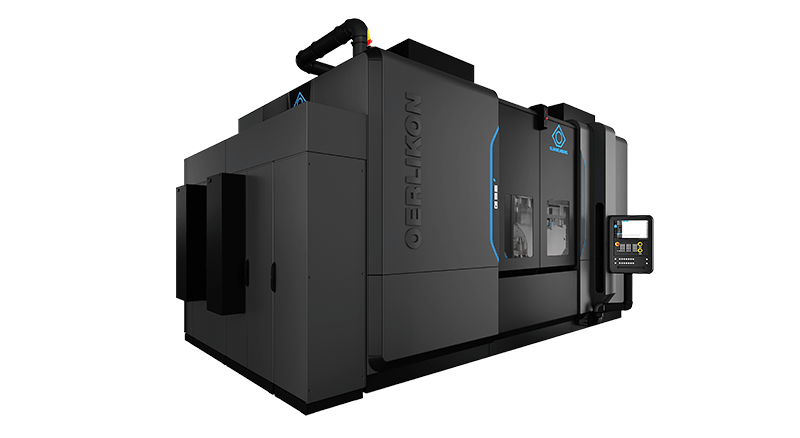

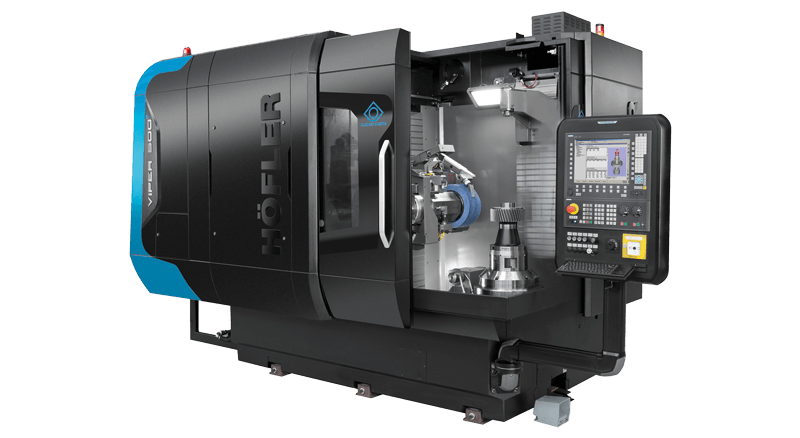

Spiral bevel gears are used to transmit torque “from the transmission to the road” in the all-wheel and rear-wheel drive systems in cars. Due to increasing performance requirements, some of the drives have to be able to transmit output of more than 300 kW. The bevel gears must also be efficient and low-maintenance, and above all quiet. The optimized machine design from Klingelnberg covers the entire spectrum of applications in the automotive industry.